Why Wooden Homes?

Sustainable Source for Wood Used in construction of Wooden Homes

Wood is a renewable resource that can contribute to sustainability in the construction industry. Wood is a natural, renewable, and sustainable material for building, with a lighter carbon footprint than steel or concrete. FSC certified sustainable wood used for Construction of Wooden Homes. With Sustainable forest at least as many new trees are grown than are harvested.

Low Embodied Energy

Sustainable timber has the lowest embodied energy compared to other building material such as steel and concrete (energy used in its processing, production and transport from tree to consumer). As the embodied carbon in the average building accounts for 30-50% of its whole carbon footprint, this has the potential to make a huge impact.

Durable and easily maintained

Wood has a high strength and durability. It also has a high breaking length – the length at which a material breaks under its own weight when hanging. Higher machinability with relatively great accuracy. Strong material with good structural properties; suitable for house construction. Relatively cheap and easy to maintain compared to other materials.

Aesthetics and Highly versatile

Sustainable timber and wood is one of the easiest ways to add an aesthetic appeal to any indoor as well as outdoor environment.

Timber homes are among the quickest to erect compared to brick or stone construction. A quicker build time clearly saves time and money. The workforce required to erect the structure is relatively small. Components of the timber homes can be easily moved and connected which makes it possible to build even at remote locations where accessibility tot site is difficult.

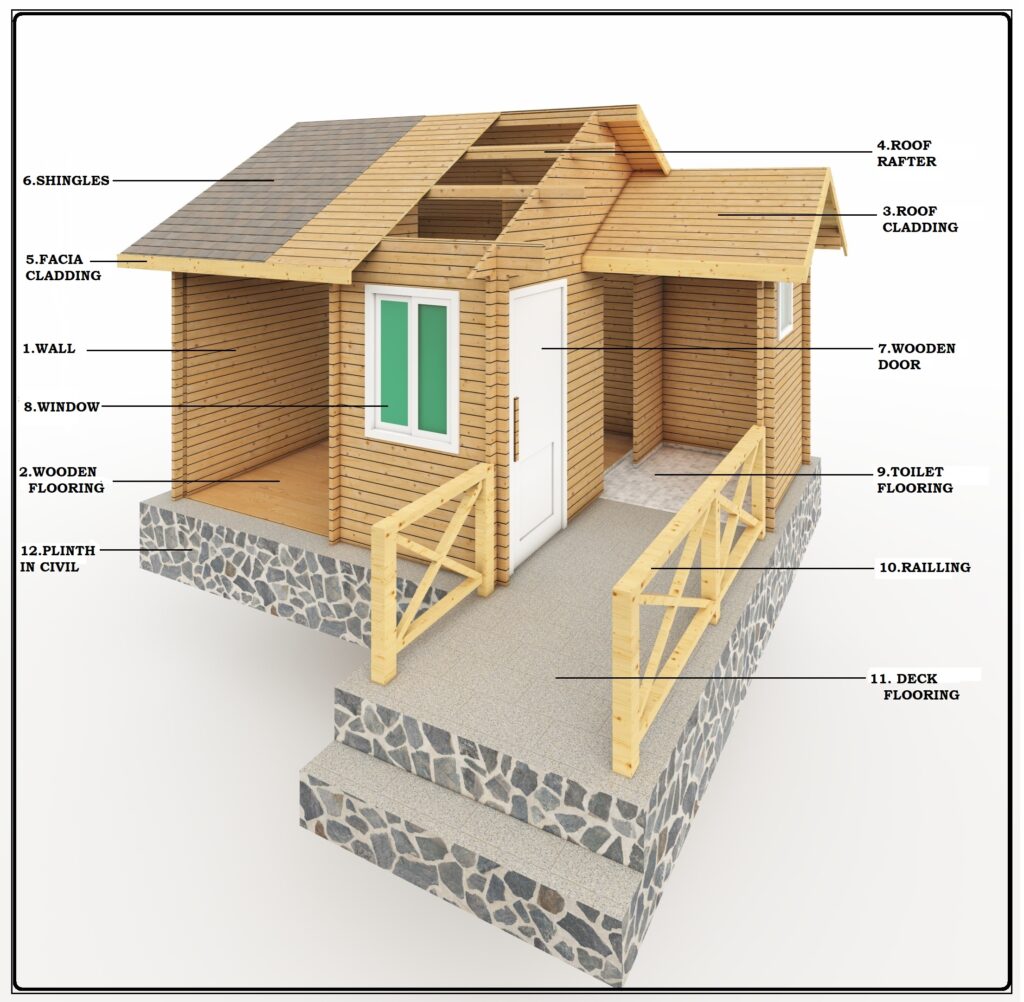

Wooden Home Components

Features

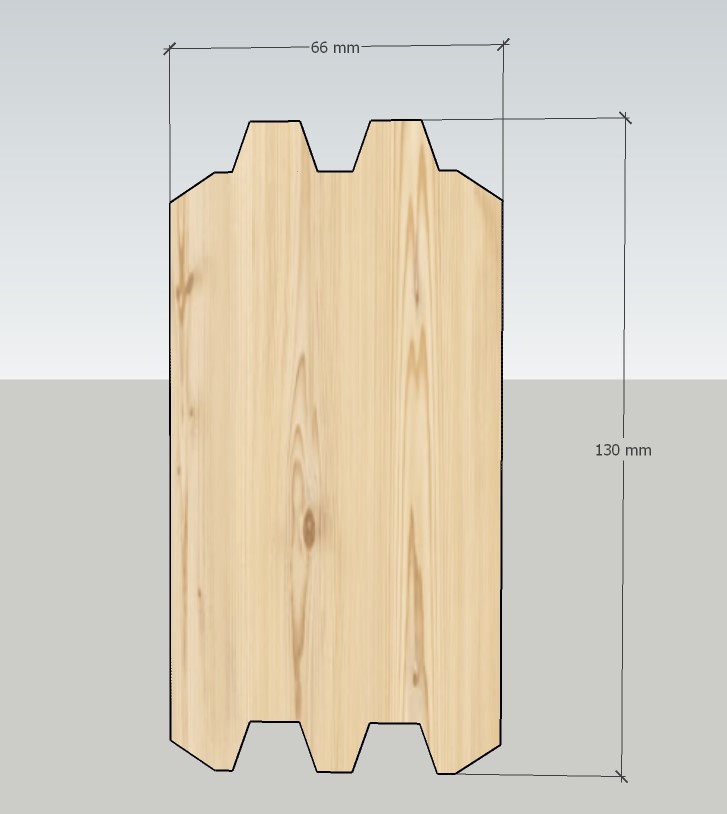

Glue-laminated profile timber.

Kiln-dried timber of standard sizes are machined and face laminated using high pressure clamps, Which are then processed to the finish size. Use of glue-laminated timber minimizes the wood defects such as check, twist, warp and shrink. Provides Dimensional stability eliminating the need for onsite rework General wall dimensions available are:- 130x 44mm

- 130x 66mm

- 130x 88mm

Interlocking Structure:

In this type of structure the horizontal wall members are joined through interlocking at the corners by notching. Notching process through highly accurate machine to achieve perfect notching air and water tight joinery.

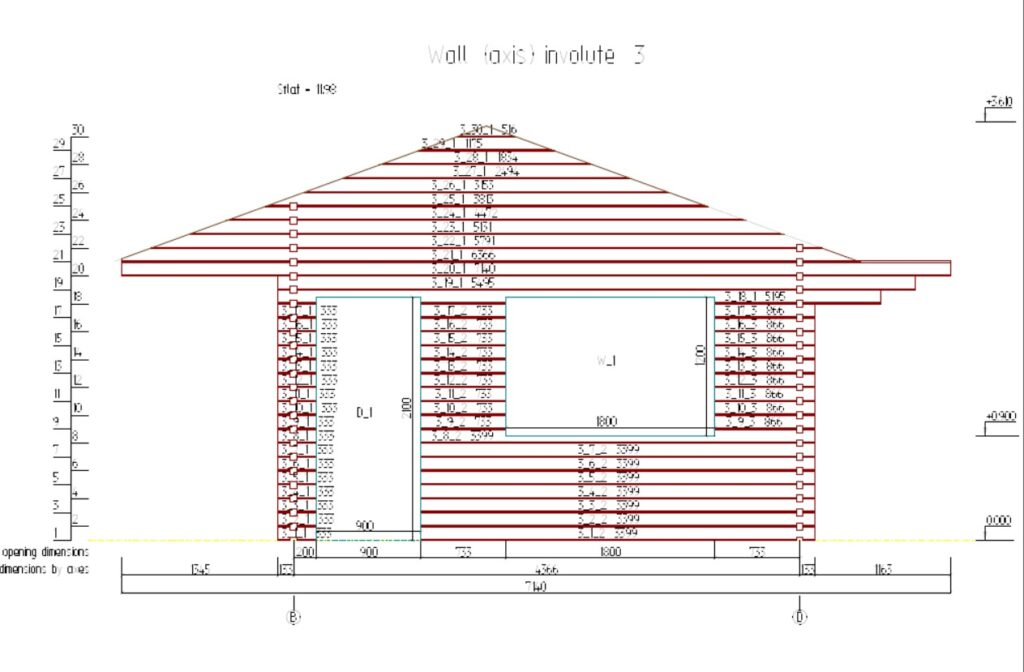

Prefabricated Structure:

Each component of the Wooden house is engineered and manufactured in-house with high accuracy. Standard connections allows for rapid installation on-site. Pre-fabrication reduces need for onsite fabrication, minimizing waste and labour cost during installation Each component of the wooden house has a unique identifier which allows easy tracking and reduced installation time. Prefabricated components are packaged in such a way to provide ease of logistics to remote locations.Process

o1

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

o2

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

o3

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

o4

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.